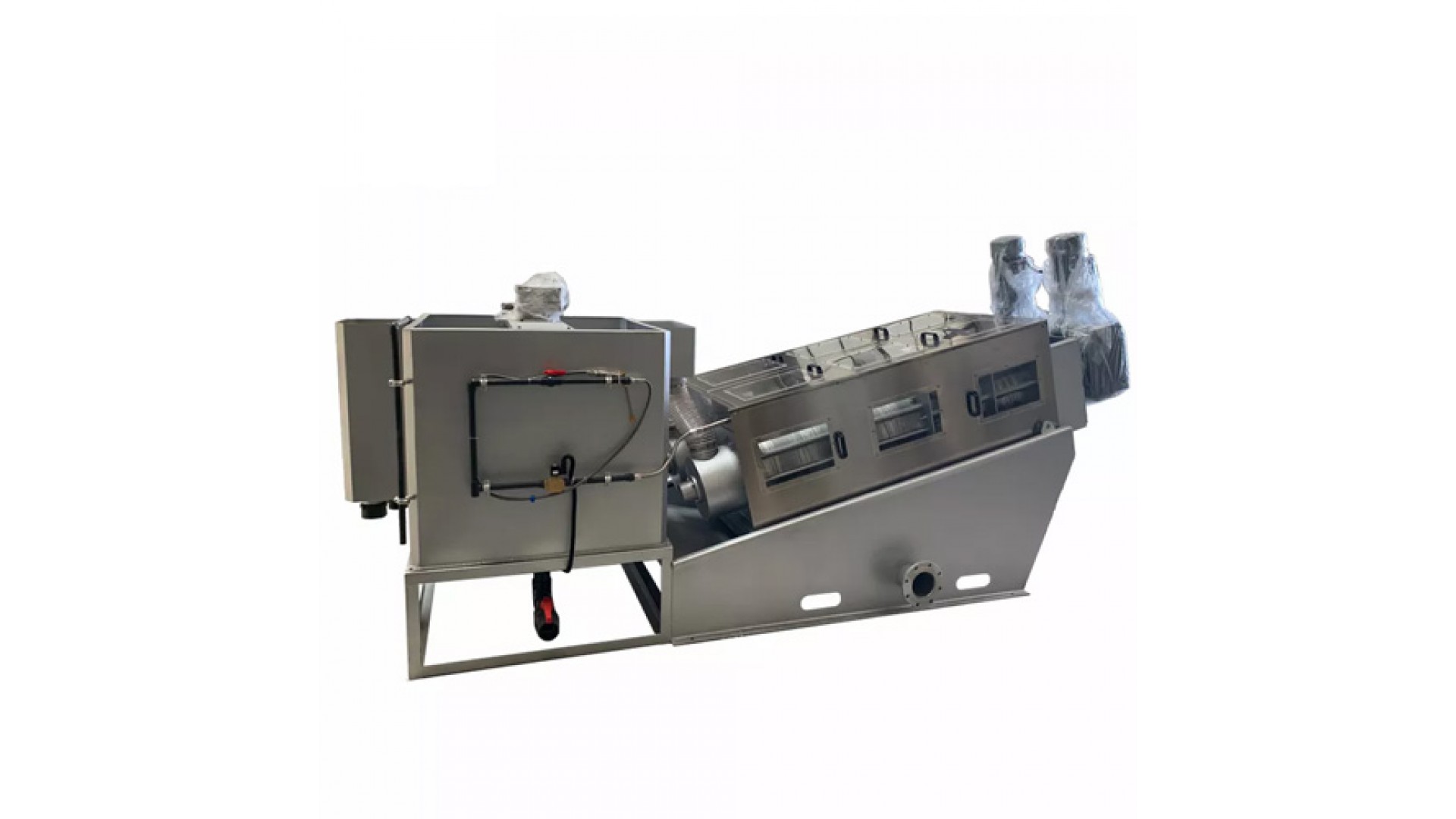

Yeni Nesil Burgu Pres Çamur Susuzlaştırma Sistemleri

Derleyen: Dr. İnş. Yük. Müh. Mete Gerçek mtgercek@uydunet.net

17 Mart 2017 | TEKNİK MAKALE Su ve Çevre Dergisi 104. Sayı (Mart 2017)

Burgu Pres ekipmanları gerek işletme maliyetlerinde sağlanan ekonomi, gerekse dayanıklılık ve bu sayede uzun yıllar problemsiz olarak verimli çalışma özelliklerinin yanı sıra işletmecilere farklı avantajlar da sağlamaktadır. Burgu pres anlamında 1985’li yıllarda ilk kez Japonya’da geliştirilen ve yeni bir çamur susuzlaştırma teknolojisi olarak bütün dünyada kabul gören “Burgu Pres” makinalarını Avrupa ilk kez, 20-25 sene kadar önce, başta IFAT olmak üzere çeşitli fuarlar sırasında tanıma imkanı bulmuştu.

Evsel ve endüstriyel atıksu arıtma çamurlarının susuzlaştırılmasında kullanılan daha önceleri genellikle tercih edilen torbalı (chamber) filtre presler, daha sonraları bantlı (belt) filtre presler ve son yıllarda burgu pres ve dekantörler belli başlı çamur susuzlaştırıcı ekipmanlar olarak karşımıza çıkmaktadır.

Özellikle endüstriyel atıksu arıtma tesislerinde atıksuyun ve arıtma prosesinin özelliklerine göre çamur susuzlaştırma konusu daha çok önem kazanmaktadır. Bu gibi durumlarda alınan çamur numuneleri üzerinde yapılacak laboratuvar testleri sonuçlarına göre en uygun çamur susuzlaştırıcı ekipman titizlikle seçilmelidir. Ekipman seçiminde tabii ki susuzlaştırılması istenen çamurun günlük miktarı, özellikle saatlik çamur miktarı (m3/saat) ve saatlik katı madde miktarı (kg.KM /saat) önem kazanmaktadır. Diğer çamur susuzlaştırıcı sistemlerde olduğu gibi Burgu Pres sistemlerinde de en önemli konu, çamur zerreciklerinin polielektrolit kimyasal maddelerle şartlandırılması ve bu sayede çamur zerreciklerinin birbirleriyle birleşip bütünleşmesiyle sağlam pıhtılar oluşturmasıdır. Pıhtılar arasında serbest kalan su, süzüntü suyu (filtrate) olarak susuzlaştırıcı ekipmanından dışarı çıkar ve geri kalan pıhtıların birbirleriyle birleşerek, parçalanmayacak şekilde sağlam yapılar oluşturarak, ki arzu edilen amaç da budur, çamur keki oluşması sağlanır.

Burgu Pres Sistemleri Hakkında...

Oldukça farklı burgulu çamur susuzlaştırıcı sistemler bulunmaktadır. Bu çalışmada en az 3, hatta benzeri ile birlikte toplam 4 ayrı sistem incelenmiştir.

Her bir sistemde helezon sistemi, yani burgu (Arşimed vidası, auger) bulunur. En önemli gerekli şart olan “Ekipmana giren çamurun polielektrolit ile şartlandırılması sayesinde sağlam pıhtılar oluşturulması (bunu sağlayacak en uygun polielektrolit madde seçimi de çok önemlidir) pıhtılaşmaya başlamış olan çamur zerreciklerinin parçalanmadan taşınması”, yani bu taşıma işleminin gerçekleşmesini sağlayan ve ekipmanın ana elemanı olan çamur girişi kısmından sonra çamur keki çıkış kısmına kadar taşıyan yatay veya eğimli bir Arşimed vidalı (auger) taşıyıcı sistem bulunmaktadır. Bu bahsi geçen burgulu çamur susuzlaştırma sistemlerini birbirinden ayıran en önemli özellikler, başta yatayla belli bir açıda imal edilen ana gövde konumudur; buna karşın diğer bazı sistemlerde yatay konumlu burgu presler gelmektedir. Buna ilave olarak diğer bir özellik de, sabit konumlu silindirik bir filtrenin iç yüzeyleri ve sabit çubuk aralıkları (yan yana gelmiş çemberler olarak gözönüne getirirsek) çember aralıklarının fırça ve yaklaşık 6 ATU basınçlı temiz kullanma suyu ile auger döndükçe belli zaman aralıklarında çalışması gereken su püskürtme tertibatı veya daha gelişmiş teknolojilerde bunun yerini alan farklı diskler birbirlerinin arasından geçerek disk aralıklarını fırça ve basınçlı suya gerek kalmadan kendi kendine temizleyebilen sistemler örnek olarak verilebilir. Sabit disklerin arasındaki hareketli disklerin hareket etmesi, auger arşimed vidasının dönme hareketi ile sağlanmaktadır.

Ayrıca tamamen yatay konumlu olup, silindirik yapıyı çemberler yerine üç boyutlu filtre membran ile oluşturan Burgu Presler vardır. Filtre yüzeylerin sabit ve hareketli disklerden oluştuğu diskli sistemde en fazla 2-3 ATU basınçlı ve 200-300 ltr/saat gibi çok az miktarda temizleme suyu kullanılmasına karşın Türkiye’de 1993 yılından beri çok sınırlı da olsa bazı tesislerde kullanılmaya başlanmış olan eski tip eğimli burgu preslerde sabit çubuklu ve filtre sistemi membranlı olan yatay konumlu burgulu preslerde 5-8 m3/saat gibi çok yüksek miktarda (ve çok sık zaman aralıklarında) filtre gözenek aralıklarını temizlemek için kullanma suyu kullanılmaktadır; aksi halde sistem çalışmaz. Sabit konumlu filtre yüzeyleri temizleme amaçlı temin edilecek kullanma suyu, 200-250 mikrondan daha az partikül içermelidir; aksi halde su püskürtme memeleri tıkanır. Süzüntü suyunun (filtrate) helezon dışına cazibe ile çıkmasını sağlamak için filtre yüzeylerin devamlı temiz kalması şart olmaktadır. Bu sayede filtrate süzüntü suyu giderinin açık olmasının garanti edilmesi için en az 5 ATU, hatta 6 ATU basınçlı (makine susuzlaştırma işlemi yaptığı sürece) devamlı olarak temizleme suyu kullanılmaktadır.

Birçok ülkede özellikle küçük ve orta ölçekli atıksu arıtma tesislerinde çalışmakta olan mevcut susuzlaştırıcı ekipmanlar özellikle işletme masraflarının fazla oluşları nedeniyle daha ekonomik olan Burgu Preslerle değiştirilmiştir. Özellikle yeni nesil diskli çamur burgu pres susuzlaştırıcı ekipmanları, atıksu arıtma tesislerinde her geçen gün daha çok tercih edilmektedir.

Burgu Pres işletme ve bakım harcamalarının diğer alternatiflere göre düşük olması, yeni nesil diskli burgulu preslerde hızlı hareket eden elemanların bulunmayışı, Burgu Presin aşınma problemlerinin silindirik konik konumlu sabit filtre içinde bulunan tek dönen eleman olan helezonun dakikadaki dönme devir sayısının evsel uygulamalarda sadece birkaç rpm olmasına bağlıdır. Oldukça düşük dönme hızı sayesinde aşınmalar azaldığı için yedek parça gereksinimi de yok denecek kadar az olmaktadır.

Burgu preslerin sağlam yapısı, sadece 1-3 rpm bazı burgu preslerde 5-12 rpm iç helezon dönme devir sayısı, 1,1-3,0–4,0 kW kurulu güçlü direct drive tek motor, sessiz ve titreşimsiz, nispeten daha az polielektrolit ihtiyacı, sürekli otomatik çalışması ve çok gelişmiş elektronik kontrol sistemi ve teknolojik imalat, ancak basit bir yapı sayesinde mümkün olabilmektedir. Bütün bu verilen özellikler ve avantajlar, ufak ve orta ölçekli evsel ve endüstriyel atıksu arıtma tesislerinde Burgu Presleri, özellikle de diskli yeni nesil burgu presleri daha üstün bir duruma getirmiştir.

Çamur girişindeki katı madde değişiklikleri ve çamur karakterinin zaman zaman değişiyor olması, diğer susuzlaştırıcı ekipmanlarda yıpranmalara, daha sık aşınan parçaların yenilenmesine ve daha çabuk yedek parçaların kullanılmasına sebep olur. Haliyle sık sık temizlik yapılmasına ve daha çok personel dikkatine ihtiyaç duyar. Bu nedenlerle önceden öngörülemeyen ilave masraflar doğar ve sonuçta işletme masrafları da oldukça artar.

Burgu pres ekipmanları tamamen sürekli tam otomatik olarak PLS sistemi ile çalışır ve sistem kendi kendini kontrol eder. Özellikle küçük ve orta ölçekli atıksu arıtma tesislerinde burgu pres susuzlaştırıcı ekipmanın tercih edilmesi, sadece elde edilen yüksek katı madde içerikli çamur kekine bağlı değil, aynı zamanda bu ekipmanların son 25 senedir bütün dünyada çok miktarda başarılı uygulamalarının olması, sorunsuz olarak mükemmel bir verimle ilk günkü gibi çalışıyor olması, sağlam, çok az insan dikkatine ihtiyaç duyuyor olması, ekonomik işletme, çok az yedek parça ihtiyacı gibi faktörlere de bağlıdır. Daha yüksek oranda katı madde içeriklerine ulaşılabilir olması, özellikle lifli çamur yapılarında, örneğin kağıt sanayi, deri sanayi, elyaflı tekstil sanayi atıksularında elde edilen çamurların yüzde 27, 30 hatta yüzde 45 KM içeriklerine kadar ulaşan çamur keklerini elde etmeyi de mümkün hale getirmiştir. Kapalı bir mekan-özel bir bina gerektirmeden dış ortamda sundurma altında bile çalışabilmesi, çok az yer kaplayan kompakt paket bir sistem oluşu, komple 304L, 316L veya 321 paslanmaz çelikten imal edildiğinden aşınma probleminin olmayışı, çok az yedek parça ve bakımın yeterli olması, otomatik olarak kendinden yıkamalı temizleme sistemi ile ve yeni nesil diskli çamur burgu preslerin çok az su kullanma avantajı ile sadece tek bir adet motor (1-4 kW ve 1-12 rpm) bulunması ile sessiz ve titreşimsiz çalışması, özellikle eğimli yapısı sayesinde preslenen çamur kekinin doğrudan (koku yaymadan kapalı bir ortamda) otomatik olarak çöp konteynerine veya depolama tankına veya römorka dökülmesi ile diğer proseslerden farklılık gösterir.

Bu proseste çamur, çamur depolama tankından, çamur yoğunlaştırıcıdan veya doğrudan çürütme tankı vb. kaynaktan, özetle çamur deposundan alınarak, oluşan çamur pıhtılarının bozulmaması için ekzantrik vidalı screw pump çamur pompası yardımıyla, burgu presin ilk ünitesi olan flokülasyon (pıhtılaşma) tankının bağlandığı boru hattına pompalanır. Bu boru hattı üzerinde bulunan bir statik karıştırıcı (mixer, mixing injection unit), koagülan hazırlama (3-gözlü toz veya sıvı polielektrolit çözeltisi hazırlama) tankından bir dozaj pompası ile basılan polielektrolit çözeltisi ile ıslak çamuru çok iyi bir şekilde karıştırır. Bu statik karıştırıcı ile ıslak çamur (thin sludge) ve genelde kullanılan toz polielektrolit (%0.01-0.05) çözeltisinin optimum bir şekilde teması sağlanır. Flokülasyon tankı (tüpü) içinde, polielektrolit çözeltisi+ıslak çamur karışımı ile meydana gelen (floc) pıhtılaşmış çamur ve süzüntü suyu karışımı seviyesi yükselir ve susuzlaştırma makinasının içine boşalır. Böylece ön susuzlaştırma işlemi gerçekleştirilmiş olur. Ön susuzlaştırılması sağlanmış (pıhtılaşmış) çamurun, sürekli olarak, (sabit ve eğik konumlu) içindeki silindirik/konik bir filter ağı (15-20 mikron) ile teması sonucunda, yeni nesil burgu preslerde sabit disklerin arasında hareketli disklerin dönme hareketi disk aralıklarından süzülen süzüntü suyu yer çekimi ivmesi ile bu filtreden dışarı/aşağı süzülür (ve deşarj edilir). Çamur kekini oluşturacak pıhtılar, silindirik filtre içinde dönen bir Arşimed vidası auger vasıtasıyla, burgu pres makinasının üst seviyesine taşınır ve çamur keki formasyonunda doğrudan konteynır içine depolanır. Sonuçta, komple otomatik olarak tamamen kapalı bir ortamda elde edilen çamur keki, direkt olarak depolama konteynerine boşaltılır.

Bu tip burgu pres yoğunlaştırıcı ve susuzlaştırıcı ekipmanlar geliştirilmeden önce çamur susuzlaştırma işleminde önemli rol oynayan etkenler aşağıda etraflıca incelenmiştir.

“Uygun ve tam dozda koagülan madde ilavesi”, “Çamurun pıhtılaşması”, “Suyun filtre edilmesi için yeterli büyüklükte filtrasyon yüzey alanı”, “Susuzlaştırma derecesine göre helezon taşıyıcı etrafındaki paslanmaz çelik ağın (filtrenin) aralıkları”, “Yeni nesil diskli burgu preslerde disk aralıkları ve hareketli disklerin dönme hızı”, “Islak çamurun sürekli olarak filtrasyon yüzeyi ile teması”, “Taşıyıcı vidanın dönme hızı ve motor gücü”, “Çamur karakterine göre paslanmaz çelik cinsi”, “Çamurun susuzlaştırma süresi”.

Eski nesil burgu preslerde filtre çubuk aralıklarının en az 5 ATU basınçlı su ile dışarıdan sık zaman aralıklarında su fışkırtılarak iyice temiz kalmasının sağlanması gerekirdi. Aksi halde süzüntü suyu helezonu çevreleyen silindirik filtre yüzey çubuk ve gözenek aralıkları tıkanır, süzüntü suyu dışarı çıkamaz ve helezon augerin çamuru süzüntü suyu ile birlikte çamur keki çıkış noktasına doğru vereceği için çamur keki oluşumu yerine sulu çamur çıkardı. Ancak yeni nesil diskli tip burgu preslerde bu dezavantaj ortadan kalkmıştır.

Yeni nesil diskli burgu pres çamur susuzlaştırıcı sistemler genel olarak aşağıdaki gibi sabit ve hareketli disklerin ve bir helezon taşıyıcının oluşturduğu yoğunlaştırma (ön susuzlaştırma) ve susuzlaştırma (helezon adımlarının aralıklarının gitgide azalması ile de ayrıca ilave) olarak çamur keki oluşumunun başladığı bir sıkıştırma bölümünden ibarettir.

İşletmecilere Sağladığı Avantajlar

Sürekli olarak tam otomatik çalışan burgu pres çamur susuzlaştırıcılarının işletmecilere sağladığı avantajlar ise şöyle sıralanabilir.

1- Her miktar çamur için en uygun makine seçimi/kombinasyonu yapılabilir. Üstün imalat teknolojisi ve standartlaştırılmış seri üretim sayesinde düşük fiyat ile çok kısa sürede teslim edilebilmektedir. Komple paslanmaz çelik olup, aşınma olmaz ve problemsiz, uzun yıllar hizmet görür. İnsan gücü gereksinimi azdır. Komple tam otomatik ve sürekli (kesintisiz) çalışır.

2- Özel bir filtre malzemesi, herhangi bir belt, plaka vb. gerekmez. Filtre paslanmaz çeliktir. Çok az enerji harcar, çok düşük devirli olup içinde aşındırıcı (kum, pomza taşı vb.) malzemeler bulunan çamurların susuzlaştırılmasında da kullanılabilir.

3- Eski tip burgu preslerde çalıştıkça 5-6 ATU basınçlı su ile otomatik olarak, belli zaman aralıklarıyla kendini temizler, filtresini yıkar. Yeni geliştirilen sabit ve hareketli disklerden meydana gelen yeni nesil burgu preslerde su ile filtre aralıklarını temizlemek gerekmez. Bu sayede önemli ölçüde su tasarrufu sağlanır. Sadece makine durduğunda 2-3 ATU basınçlı çok az miktarda su ile disk aralıkları temizlenir.

4- Kompakt olup, dış ortamda herhangi bir yerde tutulabilir. Bina içi ve özel bir tertibat gerekmez. Çok az hacim yeterlidir (6-8 m2). Montajı basit ve süratle yapılır.

5- Kullanılan polielektrolit miktarı düşüktür ve böylece ilave bir ekonomi sağlar. Çamur sürekli olarak filtre yüzeyle temas halindedir ve süzüntü suyu kolayca çamur pıhtılarından ayrılır, susuzlaştırma verimi artar. Burgu pres ekipmanlarının uzun ömürlü ve paslanmadan problemsiz iş görebilmesi için kullanma talimatlarına uymak, ucuzlatıcı tuz veya başka katkı maddeleri katılmamış orijinal polielektrolit madde kullanmak da önemlidir. Zira bilindiği gibi paslanmaz çelik, paslanır.

6- Çıkan çamur keki, eğimli gövde sayesinde doğrudan konteynıra boşalır.

7- Sessiz çalışır. Titreşim yoktur. Aşınma yok denecek kadar azdır. Minimum bakım yeterlidir. Yedek parça ihtiyacı yoktur. İşletme masrafları düşüktür.

8- Hidrolik elemanları yoktur. Prosesi ve çalışma prensibi basittir, sorunsuz çalışır.

9- Komple kapalı bir sistemdir. Koku ve havayı kirletici egzoz çıkarmaz, sıhhi ve temiz bir işletme imkanı sağlar.

İşletmelerde burgu pres çamur susuzlaştırıcı ekipmanların kullanılması, aşağıdaki dezavantajları önler:

1- Kesikli çalışmayı önler (Plakalı preslerdeki ve diğer preslerdeki kesikli çalışma gibi)

2- Yüksek miktarda aşınma nedeniyle, diğer ekipmanlarda sıkça görülen belt/plaka filtre tabakalarını değiştirme ve özellikle santrifüj döner filtresini değiştirme gibi bir zorunluluk yoktur. Zira burgu pres makinaları komple paslanmaz çelikten imal edilmektedir. Belt ve plakaların değiştirilme zorunluluğu zaman kaybının yanı sıra ilave masraf gerektirir (Belt ve plakalı preslerdeki gibi) burgu pres ekipmanında belt ve plaka yoktur, komple paslanmaz çelik filtre veya diskler vardır ve bu sayede uzun yıllar hizmet görür.

3- Devamlı insan gücü ile (manuel) temizleme gerektirmez, tam otomatik çalışır.

4- Presler için maliyeti fazlalaştıran ayrıca özel bir bina gerektirmez.

5- Çamur kekinin uzaklaştırılması (taşınması) ilave bir maliyet ve zaman gerektirir. Burgu pres ekipmanları, çamur kekini doğrudan konteynıra depolar.

6- Sessizdir. Santrifüjlerde (Hızlı ve devirli olduğu için aşınma çok olur) elektrik sarfiyatı fazladır. Burgu pres kurulu gücü (pompalar vs. dahil) yaklaşık 5 kW’tır.

7- Paslanma olmaz, burgu presler çamur ile temasta olan kısımları başta olmak üzere komple paslanmaz çelik malzemeden imal edilmiştir. Kapalı ortamdır koku, egzoz gazı vb. koku çıkartmaz, temiz ve problemsiz işletilir.

8- Nakliyede özel bir sorun çıkmaz, burgu pres hem kompakttır, hem de sağlamdır.

9- Birçok tesiste senelerdir başarıyla kullanılmıştır.

10- Montaj kontrolü ve işletmeye alma (start-up) uzman ekip tarafından gerçekleştirilir.