Allen Hazen (28 Ağustos 1869 - 26 Temmuz 1930) Amerikalı bir inşaat mühendisiydi ve hidrolik, taşkın kontrolü, su arıtma ve kanalizasyon arıtma konusunda uzmandı. Kariyeri 1888'den 1930'a kadar sürdü ve belki de en çok Hazen-Williams denklemiyle hidroliğe yaptığı katkılarla tanınıyor. Hazen, sedimantasyon ve filtrasyonla ilgili bazı ufuk açıcı çalışmaları yayınladı.

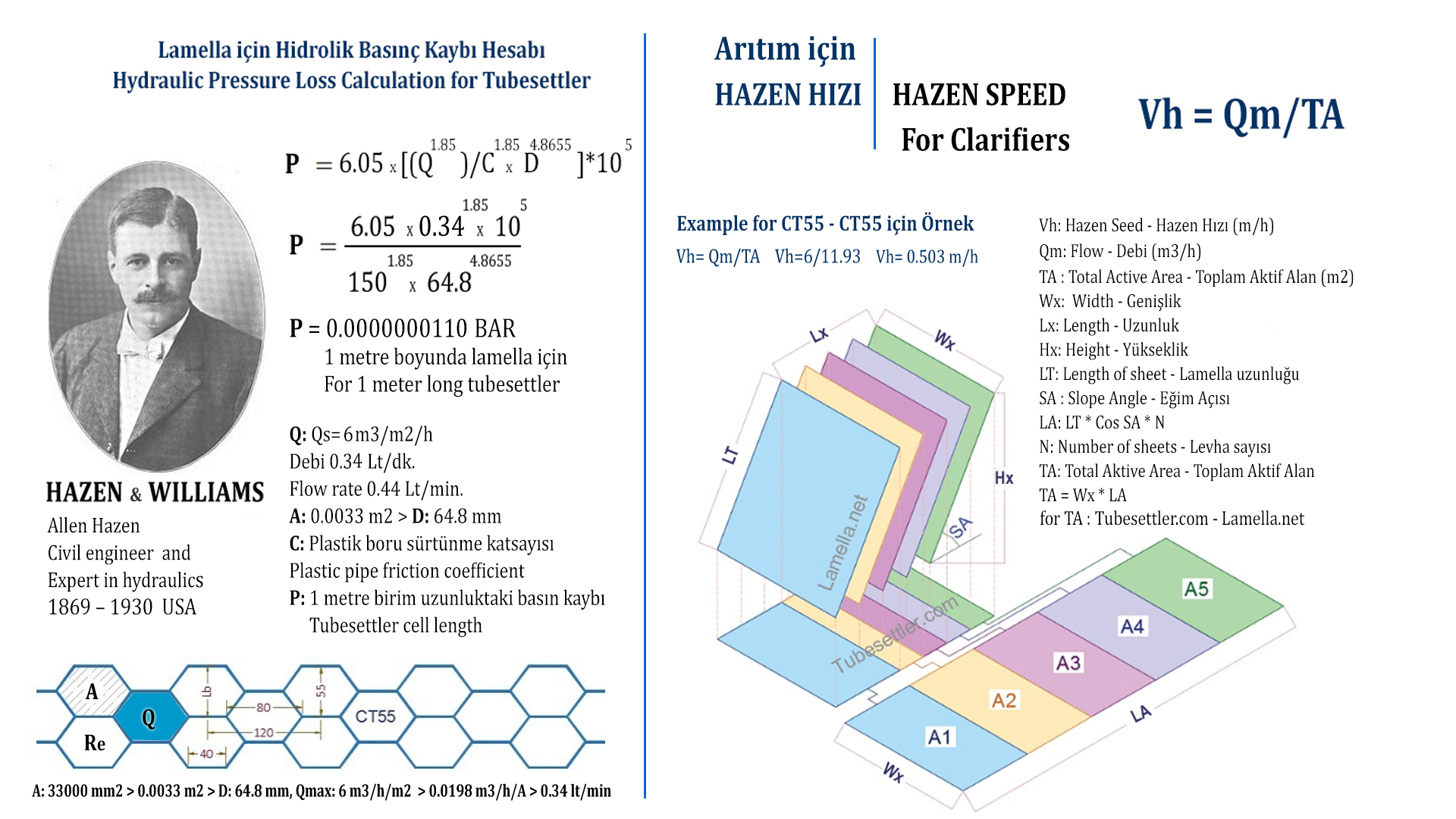

Hazen en çok 1902'de Gardner S. Williams ile birlikte boru hatlarındaki suyun akışını tanımlayan Hazen-Williams denklemini geliştirmesiyle tanınır. Bu denklem, akışkanlar için boru yüzeylerindeki sürtünmeden kaynaklanan basınç kaybını ifade eder. Hazen-Williams katsayısı olarak bilinen bir sabiti kullanır.

Hazen'in yavaş kum filtrelerinin tasarımına yönelik bazı temel parametreleri oluşturdu. Filtrasyon teknolojisine en büyük katkılarından biri, filtre ortamının boyut dağılımını tanımlamak için iki terim geliştirdi.

Etkin boyut ve tekdüzelik katsayısı.

Bu iki parametre günümüzde su arıtma tesislerindeki filtre malzemelerinin boyutunu belirlemek için kullanılmaktadır.

Allen Hazen tarafından formüle edilen “Hazen Teorisi” su arıtma alanında, çökeltme tankı veya durultucu tasarımında temel bir prensibini oluşturur.

Bu teori, suda asılı parçacıkların çökelme davranışlarının anlaşılmasına yardımcı olan matematiksel bir ilişki sağlar.

Bu teori, parçacıkların akışkan bir ortamda yerleşme hızı ile alakalıdır.

Teori parçacıkların çökelme hızı, boyutu, şekli ve içinde asılı kaldıkları akışkanın özellikleri arasındaki ilişkiyi tanımlar.

Hazen Teorisi, bir parçacığın bir sıvı içindeki çökelme hızının, çapının karesi ve parçacık ile sıvı arasındaki yoğunluk farkıyla orantılı olduğu kavramını ortaya koyar. Hazen Teorisi, “Hazen Hızı”olarak da bilinir. Şu denklem ile ifade edilir.

Vh=k⋅d2⋅(ρp−ρf)/μ

Vh: parçacığın yerleşme-çökme hızıdır.

k :bir sabittir.

d parçacığın çapıdır.

ρp: parçacığın yoğunluğudur.

ρf: sıvının yoğunluğudur.

μ: sıvının dinamik viskozitesidir.

Bu denklem, yapılacak arıtma tesisinin çökelme verimini tahmin etmelerine yardımcı olur. Su arıtma tesislerinde çökeltme tankları ve durultucu tasarımı için çok önemli bir araçtır. Askıdaki katı maddelerin sudan uzaklaştırılmasını sağlamak için tank boyutu, akış hızları ve parçacık özellikleri gibi parametrelerin değerlendirilmesine olanak tanır.

"Hazen Hızı" mühendislik ve akışkanlar dinamiğinde kullanılan bir ölçümü ifade eder. Hidrolik sistemdeki akış hızını hesaplar. Hazen Speed, adını sıhhi mühendislik ve akışkanlar mekaniği alanındaki çalışmalarıyla tanınan ünlü mühendis Allen Hazen'den almıştır.

"Hazen Hızı" yaygın olarak suyun berraklığını ölçmek için kullanılır. Hazen Ölçeği, genellikle berraklığını veya bulanıklığını değerlendirmek için basit bir yöntemdir. Suyun berraklığı bulanıklık birimi olan (NTU) ile ölçülür.

NTU su kalitesinin yanı sıra içme ve endüstriyel kullanım amaçlı suyun kalitesini göstermesi açısından önemlidir.

Hazen hızı değeri ne kadar düşük olursa su o kadar berrak olur.

Lamelli ile çökeltim tanklarında “Hazen Hızı” veya ““Hazen Teorisi” formülü şu şekildedir.

Vh=Q/TA Q=6(m3/h )/ 11.93 (m2/) =0.503 m/h

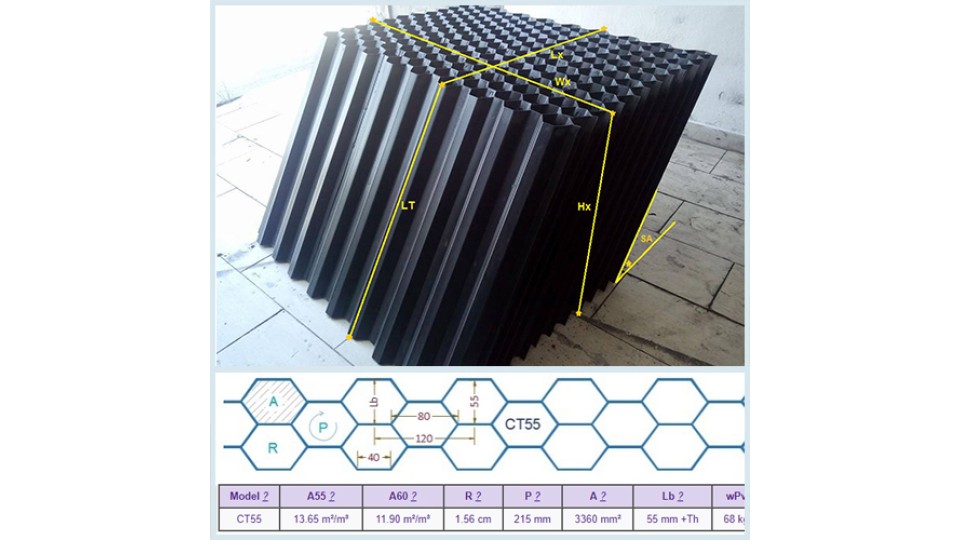

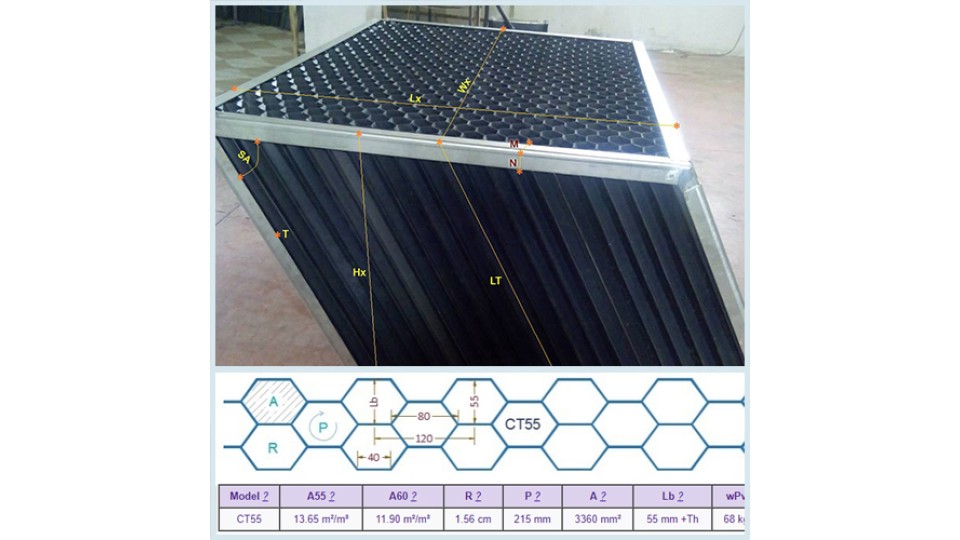

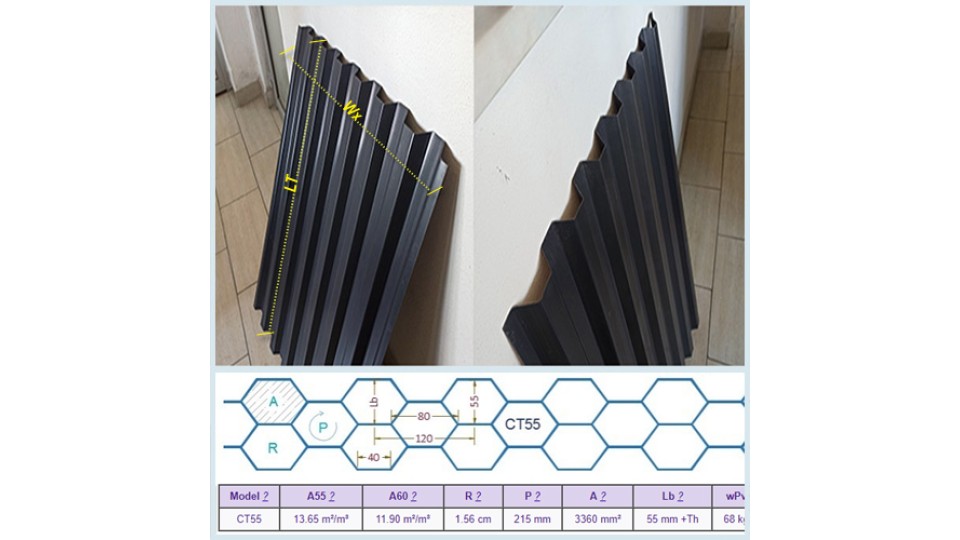

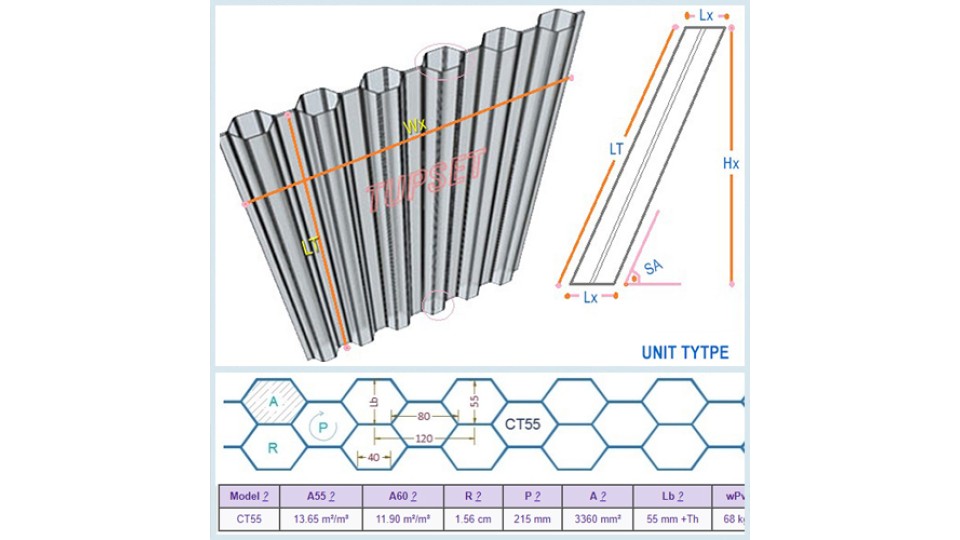

CT55 Model Lamella için; Q:6 m3/h, A60: 11.93

Vh: Partikül çökelme hızı (m/h)

Q: Debi (m3/h)

TA: Lamella Toplam Aktif Alanı ( Her model için farklıdır- Lamella.net de A55 ve A60 olarak verilmiştir.)

L: Lamella uzunluğu, C: Plastik boru sürtünme katsayısı, A: CT55 model lamellanın 1 göz hücre alanı (alandan dairesel kesite dönüşüm yapıldı) , Q: Üst yüzey yükü 6 m3/m2/h seçildi ( buna göre 1 göz hücre kesiti 0.0648 m2 den geçen su debisi 0.0252 m3/h olur.) - Vs: m/h. 1 Göz den su geçiş hızı Vs=Q/A,= (0.0252/0.0648 =0.389 m/h)

Lamella için hidrolik yük kaybı;

Boru ve kanallar göre Lamella uzunluğu azdır (1-2 metre) ayrıca lamella petek gözlerinden geçen su hızı boru ve kanaldan geçen su hızına göre çok çok azdır. Bu sebeple lamella gözlerinde hidrolik yük kaybı fazla olmaz. 1-5 mm civarında olup İhmal edilebilir seviyededir.

Hazen-Williams Hesabı - Exel

Derleyen: ahmetkemalsan@gmail.com - ARITIM.NET